The purpose of the granite inspection plate is to provide an ideal reference surface for high-precision measurement, inspection, and marking of workpieces. Due to the characteristics of the material, the measurement slides smoothly and smoothly without any stagnation. Provides a high-precision measurement reference plane for the measurement of high-precision parts. Its material is not metallic, so it is not affected by magnetism and has no plastic deformation.

Granite plate production standard: manufactured according to the national standard JB/T7975-1999.

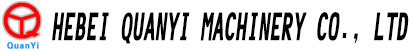

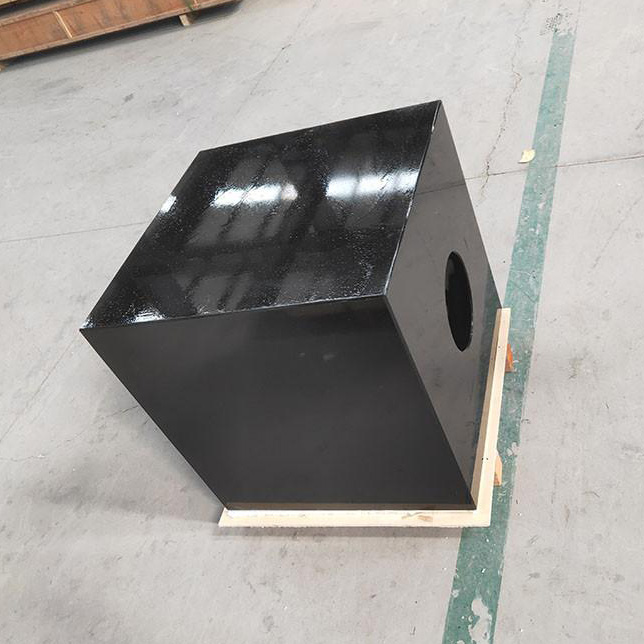

The granite inspection plate is made of high-quality "Mount Taishan Green" natural granite by mechanical processing and manual polishing. Black luster, precise structure, uniform texture, and good stability. High strength and hardness. And it has advantages such as no rust, acid and alkali resistance, no magnetization, no change in shape, and good wear resistance. Can maintain stability under heavy loads and general temperatures.

Material characteristics and advantages of granite plate and granite inspection plate:

1. It does not deform, has high hardness, and strong wear resistance.

2. Wear and corrosion resistance, high temperature resistance, and maintenance free.

3. Physically stable, organized meticulously, with grains falling off due to impact, no burrs on the surface, and no impact on its flatness accuracy. As a precision structural component of granite, its working surface is easy to maintain and maintain during use, with stable materials that can ensure long-term non deformation, low coefficient of linear expansion, high mechanical accuracy, rust prevention, anti magnetism, and insulation.

Performance of granite plate and marble inspection platform:

1、 The rock undergoes long-term natural aging, with a uniform organizational structure, extremely low coefficient of linear expansion, complete disappearance of internal stress, and no deformation.

2、 Good rigidity, high hardness, strong wear resistance, and small temperature deformation.

3、 Not afraid of acid and alkali erosion, not prone to rust, does not require oil, is not prone to sticking fine dust, maintenance is convenient and simple, and has a long service life.

4、 There will be no scratches, not hindered by constant temperature conditions, and the temperature measurement accuracy can be maintained at room temperature.

5、 Non magnetized, able to move smoothly during measurement, without any sluggishness, unaffected by moisture, and well balanced on a flat surface.

The main mineral components of granite are pyroxene, plagioclase, a small amount of olivine, biotite, and trace amounts of magnetite. It has a black color and precise structure. After billions of years of aging, the texture is uniform, stable, strong, and hard. Granite and marble workbenches can maintain high accuracy under heavy loads. Suitable for industrial production and laboratory measurement work.

The physical properties of granite:

Specific gravity: 2970-3070kg/m3

Compressive strength 245-254N/m ²

Elastic grinding amount: 1.27-1.47N/m2 ℃

Linear expansion coefficient: 4.6 × 10-6/℃

Water absorption rate: 0.13%

Shaw strength: Hs70 or above

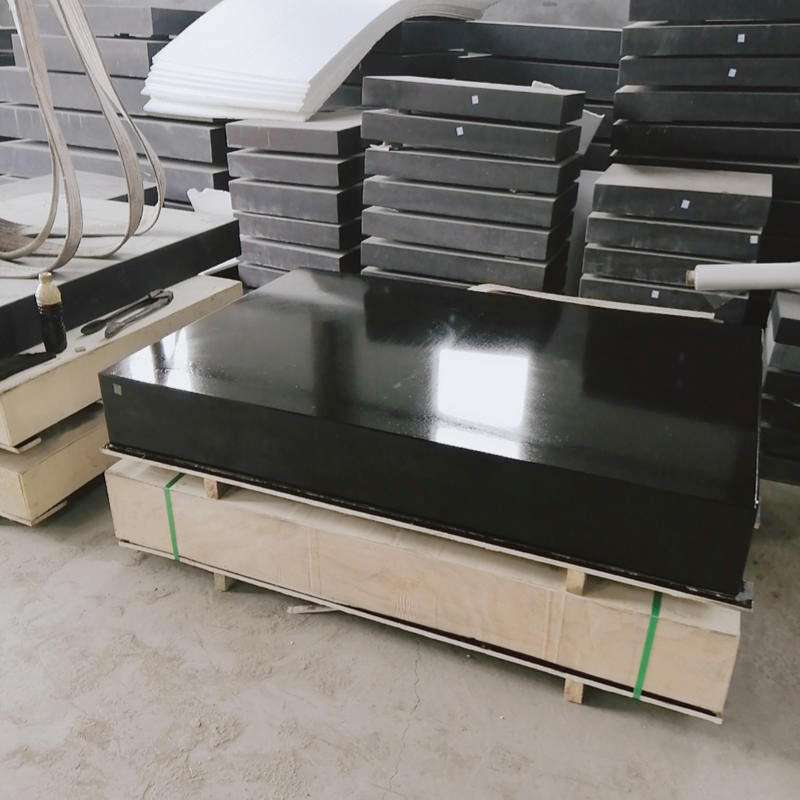

Granite inspection plate, marble platform, marble flat packaging:

Packaging of granite plate : fully sealed wooden boxes are used for packaging, and shock-absorbing strips and industrial blankets are added.

Granite is a plate usage note:

The granite plate should not be too high or too low as the usage environment is controlled within a constant temperature environment. The measured temperature is generally 20 ± 2 ℃

2. The granite plate should be used in conjunction with the platform support after adjustment.

3. Due to the unique material of granite plate , special attention should be paid during the lifting and transportation process. Nylon lifting straps should be used for lifting, and heavy pressure and collisions should be avoided during transportation.

After 6 months of normal use, the marble platform should be horizontally readjusted.