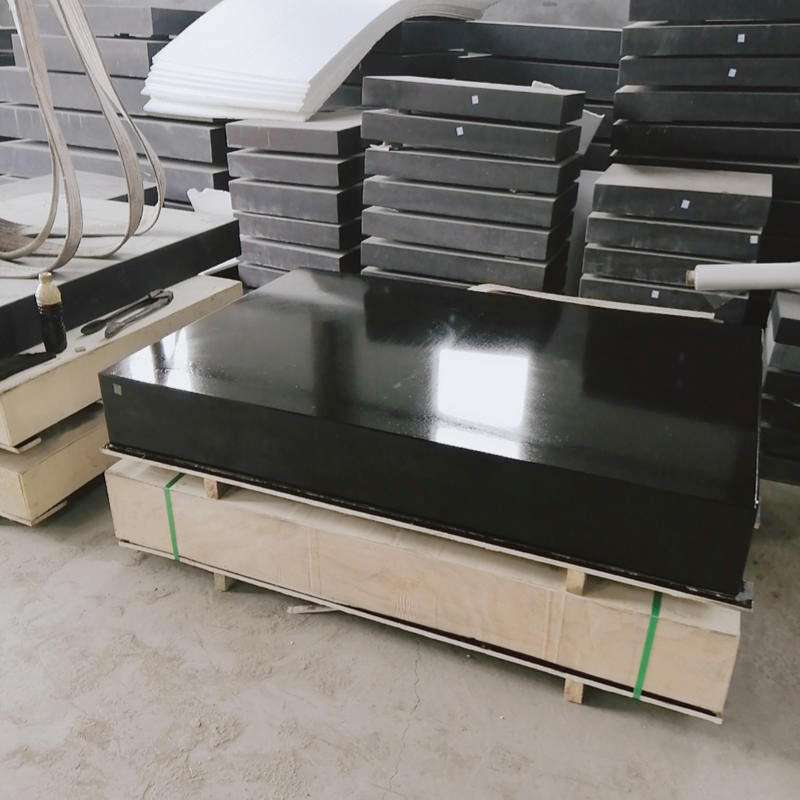

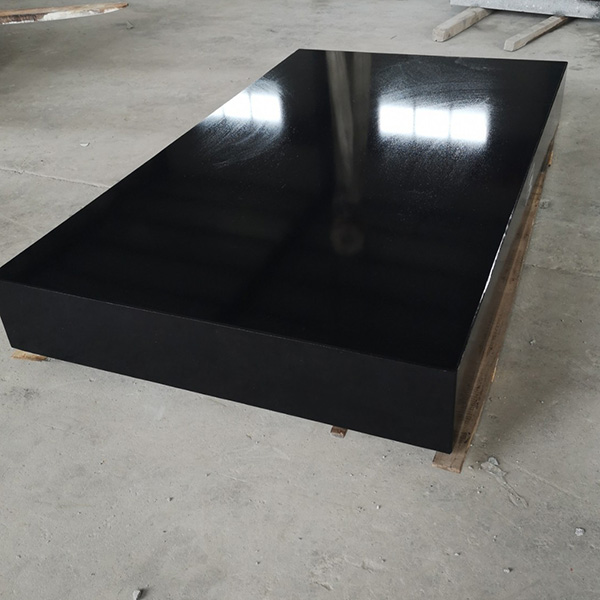

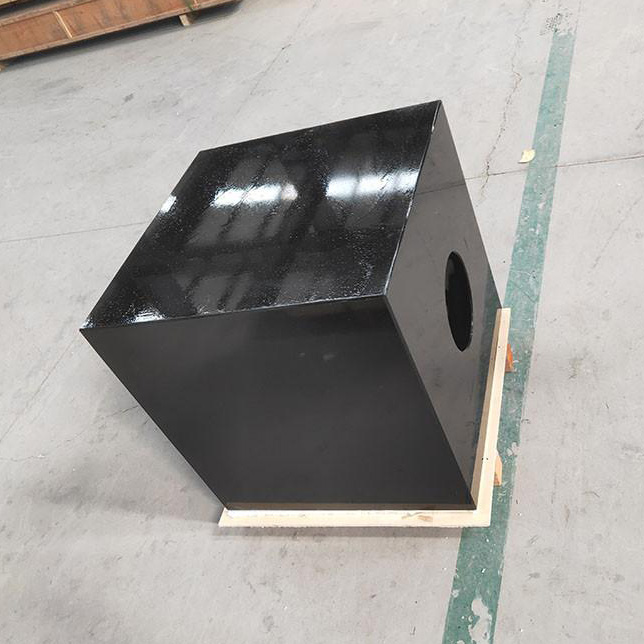

The main mineral components of the marble marking platform are pyroxene, plagioclase, a small amount of olivine, biotite, and trace amounts of magnetite, with a black luster and precise structure. After billions of years of aging, the texture is uniform, stable, strong, and hard, and can maintain high precision under heavy loads. Used in industrial production and laboratory measurement work.

The marble marking platform is made of high-quality natural marble through mechanical processing and manual precision grinding. Black luster, precise structure, uniform texture, and good stability. High strength and hardness. And it has advantages such as no rust, acid and alkali resistance, no magnetization, no change in shape, and good wear resistance. Can maintain stability under heavy loads and general temperatures.

A marble platform is a precision reference measuring tool made of natural stone materials, which is an ideal reference plane for the inspection of instruments, precision tools, and mechanical components. Especially for high-precision measurements, due to its unique characteristics, cast iron flat plates pale in comparison.

Features of marble marking platform:

① Dense organizational structure, smooth and wear-resistant surface, and low roughness values;

② Marble undergoes long-term natural aging, and the internal stress completely disappears. The material is stable and will not deform;

③ Acid resistant, alkali resistant, corrosion resistant, and anti magnetic;

④ Will not rust due to moisture, easy to use and maintain;

⑤ The coefficient of linear expansion is small and less affected by temperature;

⑥ After being collided or scratched on the working surface, only pits will be produced, without any protrusions or burrs, which will not affect the measurement accuracy.

The main disadvantage of rock slabs is that they cannot withstand excessive impacts and impacts, and high humidity can cause deformation, with a moisture absorption of 1%. Requirements for marble platform working face:

The working surface of the marble marking platform shall not have defects such as sand holes, shrinkage, scratches, scratches, air holes, cracks, slag rust, etc. that seriously affect the appearance and performance. Dents or corners on non working surfaces of marble platforms are allowed for repair.