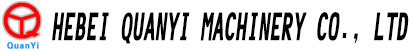

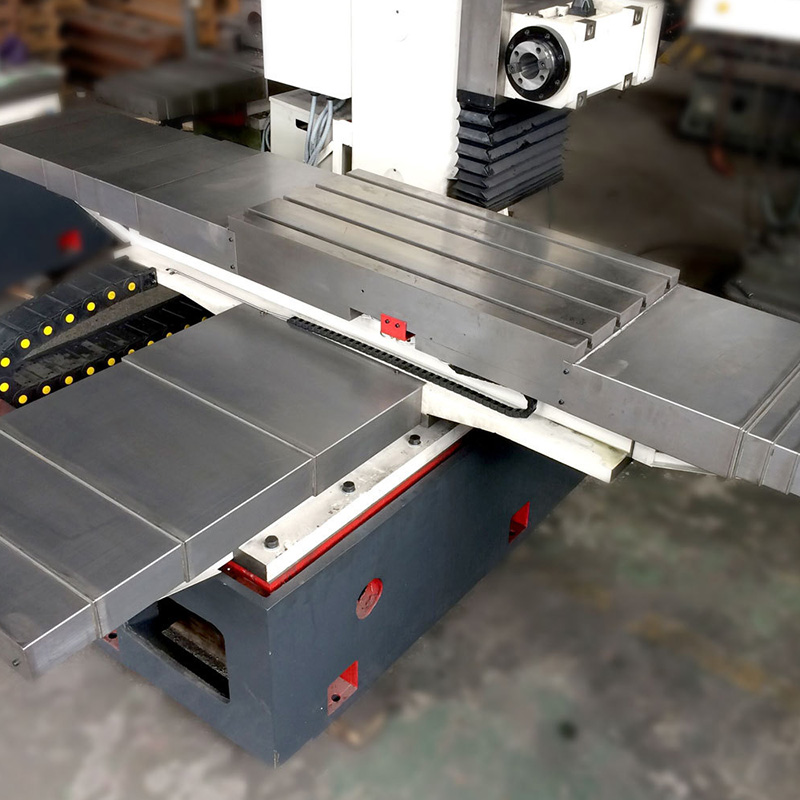

The CNC mechanical slide series adopts ball screws. This slide adopts HT250 cast iron guide rail.

This slide adopts a double closed structure (between two guide rails), with high accuracy; The precision level adopts plastic guide rail plates, which have good dynamic performance. This slide table has high stiffness, small thermal deformation, and high feed stability, thereby achieving actual accuracy under processing conditions (load). This slide table is easy to achieve stepless speed change and CNC control. Therefore, it is an ideal component for achieving high-precision flexibility

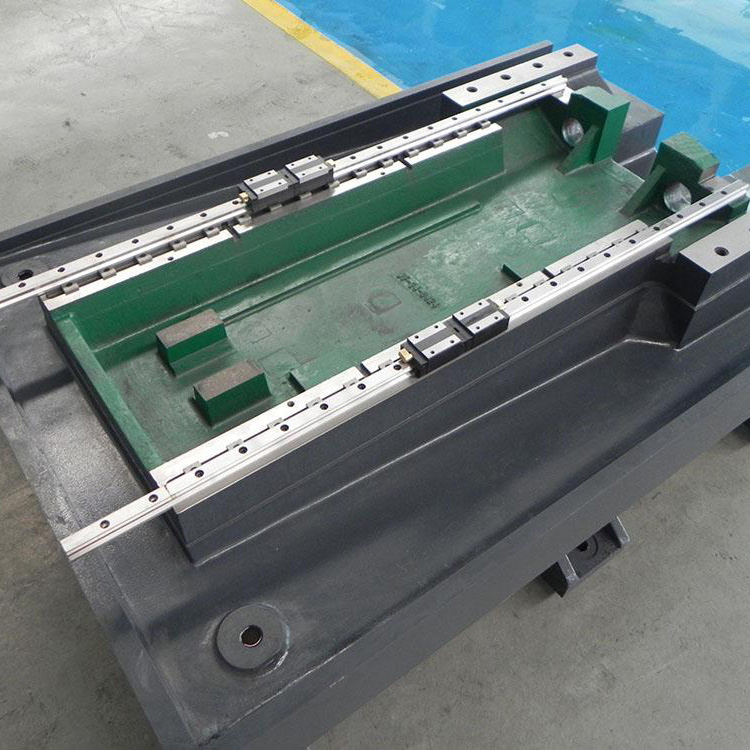

Mechanical slide table is a feed mechanism provided by modular machine tools, end milling machines, end drilling machines, and other specialized machine tools. The mechanical slide consists of a bed, skateboard, screw, gearbox, etc. Its structure is simple and easy to maintain. The working principle of a mechanical sliding table is that the skateboard moves longitudinally on the bed due to its screw drive, combined with the function of a gearbox. Multiple operating speeds such as speed can be obtained. With the development of the mechanical industry in recent years. On the basis of the original mechanical slide, a CNC mechanical slide has evolved, which is based on the original mechanical slide. Replace the ordinary lead screw with a ball screw and embed a linear guide rail on the cast iron guide rail surface. Replace the gearbox motor with a servo motor and gearbox. Enable the slide to move forward and backward quickly. Use ball screws and wire rails to achieve high accuracy.

Multiple milling cutters can be used to process surfaces simultaneously on a mechanical slide, resulting in higher production efficiency. It is suitable for batch and single piece production, and is used to process medium and large workpieces. The mechanical sliding table can rough and precision process the horizontal plane, vertical plane, inclined plane, T-shaped groove, various combination planes, and boring holes of various large and medium-sized parts. The machine tool bed guide rail undergoes heat treatment technology, and the workbench guide rail is equipped with embedded alloy lining plates and centralized pressure lubrication (which is generally applied with plastic), which can reduce wear, maintain accuracy, and extend the service life of the machine tool. The guide rail is equipped with a retractable protective cover, a microcomputer digital display automatic timed oil supply lubrication system, and machine tool lubrication protection conditions. The machine tool is equipped with AC variable frequency vector control with ball screws and optical rulers, achieving stepless speed change. The horizontal beam can be relaxed and clamped automatically; Digital display hanging button station, centralized control and adjustment, convenient operation. The cost-effectiveness it has.

The proper selection of the mechanical sliding table is related to the performance and economy of the whole modular machine tool. The sliding table is usually designed according to the size of the main power components (i.e. cutting force and feed force). The sliding table generally selects the main power components with the same specification or a size larger. The precision machining machine tool generally selects the precision sliding table. The hydraulic sliding table is selected for the machine tool with hydraulic fixture on the sliding table. The CNC sliding table is selected for the machine that needs multiple positioning. The rigid horizontal boring selects the B-type guide rail sliding table. The sliding table generally does not have lubrication devices. If it needs to be ordered, it can be noted. When the sliding table is combined with other components, the sliding table will supplement the processing of the connection holes on its working table. This product has a clearance elimination mechanism for screw and nut, suitable for reverse milling and forward milling cutting. Adopting a triangular planar guide rail combination, it has good guiding performance and high linear motion accuracy. There are fast forward (backward) and work forward (backward) gears, which can be integrated according to the needs of the workpiece processing technology, so the work efficiency is higher. There is a motor drive, the overall size of the feed box is small, and there are two electromagnetic clutches to prevent overload.